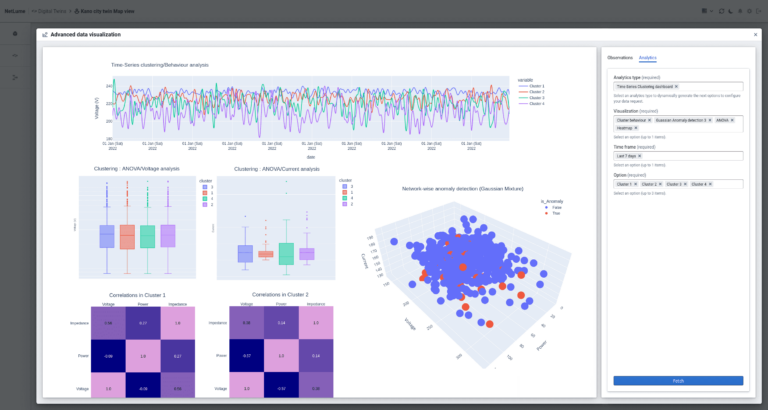

In the era of Industry 4.0, where technological advancements redefine the landscape of manufacturing, NetLume stands at the forefront as an All-In-One Data platform tailored for AI applications and Industrial IoT. This revolutionary platform empowers businesses to transform their operations seamlessly by providing a comprehensive suite of tools and features. Let’s delve into the realm of IoT applications in manufacturing and explore how NetLume, as a leader in this space, is shaping the future of industries.

1. Predictive Maintenance: Transforming Downtime into Productivity

One of the key challenges in manufacturing has always been maintaining equipment reliability and reducing downtime. With NetLume’s IoT capabilities, predictive maintenance takes center stage. By leveraging real-time data from sensors and devices, operation managers can proactively identify warning signs, schedule timely maintenance, and ensure equipment remains operational. This not only saves millions in operational expenditures but also elevates Overall Equipment Availability, allowing systems to stay online while workers stay focused on their tasks.

How NetLume Leads: NetLume’s platform facilitates the integration of sensors and devices seamlessly, offering a unified interface for real-time monitoring. The automated life-cycle management ensures that predictive maintenance becomes an integral part of your manufacturing strategy.

2. Digital Twins for Enhanced Product Development

In the realm of product development, NetLume introduces the concept of Digital Twins. This groundbreaking feature replicates the manufacturing process in a digital form, allowing managers to analyze efficiency, effectiveness, and accuracy. Retrofitting sensors to gather data from the digital replica provides insights into potential bottlenecks, enabling the creation of improved product versions.

How NetLume Leads: With a user-friendly drag-and-drop interface, NetLume empowers businesses to design their domain models effortlessly. The platform’s seamless integration of IoT devices ensures that data from digital twins is readily available for analysis, fostering innovation and continuous improvement in product development.

3. Revolutionizing Asset Utilization

NetLume redefines asset management by maximizing asset utilization through the Industrial Internet of Things. Cloud-based applications automate data analytics, generating real-time Key Performance Indicators (KPIs) for small to medium-sized manufacturers. This democratization of operational analytics enables businesses to optimize their manufacturing operations efficiently, achieving significant returns without significant capital expenditure.

How NetLume Leads: The platform’s low-code to no-code interface simplifies the process of connecting assets and systems, providing a rapid prototyping environment. NetLume’s asset management solutions go beyond just providing information; they trigger changes that enhance asset utilization, making it a transformative force in the manufacturing landscape.

4. Streamlining Supply Chain Management

In the complex world of manufacturing, supply chain management plays a pivotal role. NetLume’s IoT capabilities offer real-time tracking and tracing of inventory states, providing manufacturers with insights into available resources, Work in Process, equipment collection, and delivery dates of raw materials. This ensures cross-channel visibility, reducing mismanagement and operational inefficiencies.

How NetLume Leads: NetLume’s platform seamlessly integrates with existing ERP systems, eliminating the need for manual documentation. This integration enhances visibility into multiple departments, facilitating informed decision-making and reducing expenditures associated with lack of analysis in the organization.

NetLume: Pioneering the Future of Manufacturing with IoT

NetLume’s commitment to revolutionizing manufacturing goes beyond just providing a platform; it’s about empowering businesses to embrace the future with confidence. The platform’s intuitive design, coupled with its robust IoT capabilities, positions NetLume as a leader in shaping the Industry 4.0 landscape. As manufacturing journeys into a new era, NetLume stands as a beacon, illuminating the path to efficiency, innovation, and unparalleled success.