The manufacturing sector is undergoing a revolutionary transformation with the integration of Industrial Internet of Things (IIoT) technologies. At the forefront of this transformation is the concept of the digital twin. A digital twin is a dynamic, virtual representation of a physical object, process, or system, created by leveraging data from sensors and advanced analytics. This technology not only mirrors the physical world but also enhances it with real-time insights and predictive capabilities.

The Essence of Digital Twin Technology

Digital twin technology bridges the physical and digital worlds through a seamless data exchange known as the digital thread. This connection enables continuous monitoring and optimization of industrial operations, driving efficiency and reducing downtime. By replicating physical assets in a virtual environment, manufacturers can anticipate issues, streamline operations, and enhance decision-making processes.

Benefits of Digital Twin Technology in Manufacturing

1. Predictive Maintenance: Digital twins allow for early detection of equipment anomalies, enabling proactive maintenance and minimizing unplanned downtime.

2. Enhanced Operational Efficiency: By providing a comprehensive view of the production process, digital twins facilitate better resource management and process optimization.

3. Improved Product Quality: Continuous monitoring and real-time analytics ensure that products meet quality standards, reducing defects and waste.

4. Accelerated Innovation: Virtual simulations and testing enable faster development cycles and innovative solutions without the need for physical prototypes.

5. Cost Reduction: By optimizing processes and preventing equipment failures, digital twins contribute to significant cost savings in maintenance and operations.

Implementation Levels of Digital Twin Technology

Digital twin technology can be applied at various levels within the manufacturing process:

– Component Level: Focuses on critical individual components, ensuring their optimal performance and longevity.

– Asset Level: Involves creating digital replicas of entire pieces of equipment, facilitating comprehensive monitoring and maintenance.

– System Level: Covers entire production lines, enhancing overall efficiency and coordination.

– Process Level: Encompasses the full lifecycle of a product, from design and production to end-use, driving continuous improvement and innovation.

NetLume: Leading the Charge in Industrial IoT and Digital Twin Technology

NetLume stands at the cutting edge of Industrial IoT solutions, offering an all-in-one data platform that empowers businesses to harness the full potential of digital twin technology. Here’s how NetLume can transform your manufacturing operations:

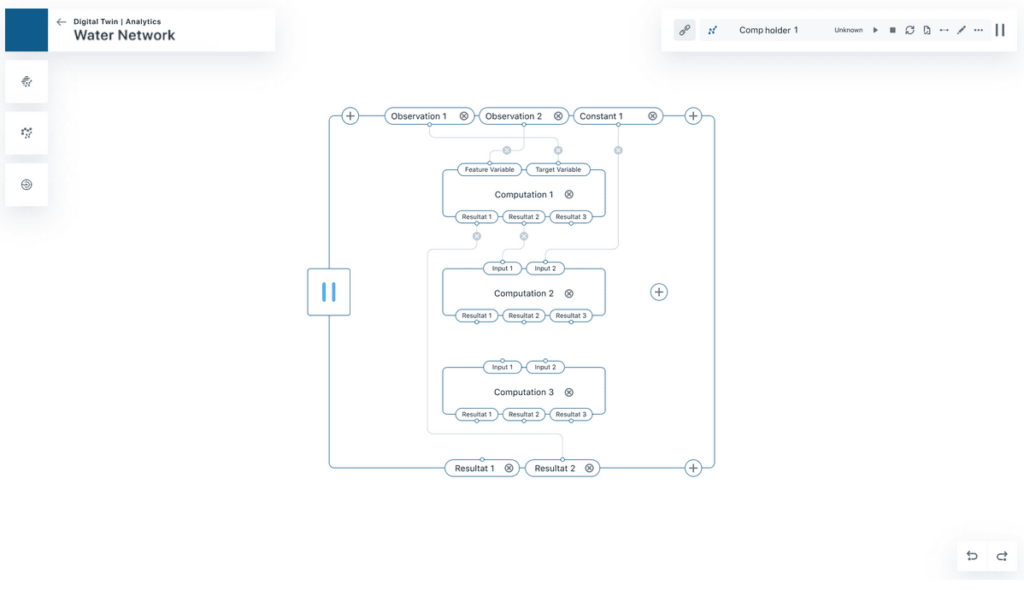

1. Domain Modeling with Ease: NetLume allows users to model their manufacturing domain effortlessly using a no-code, drag-and-drop interface. From defining the components of an electricity grid to configuring factory systems, users can create digital replicas quickly and efficiently.

2. Real-Time Insights: With NetLume, businesses can connect their data streams to the platform, deploy machine learning models, and receive real-time insights into their operations. This ensures that decision-makers are always equipped with the most up-to-date information.

3. Customizable Visualization: The platform offers customizable maps and dashboards, providing a rich library of visualizations that help monitor and manage networks effectively. Users can integrate AI models into these visualizations for enhanced analytical capabilities.

4. Automated Lifecycle Management: NetLume simplifies the lifecycle management of connected solutions, ensuring that all processes are unified and automated for maximum efficiency.

5. Low-Code to No-Code Flexibility: The platform’s user-friendly interface enables the design and deployment of AI models and data pipelines without extensive coding knowledge, making advanced analytics accessible to all users.

The Future of Manufacturing with NetLume

As the manufacturing sector continues to embrace digital transformation, NetLume is poised to lead the way with its robust and innovative platform. By integrating digital twin technology, manufacturers can achieve unprecedented levels of efficiency, innovation, and cost savings. NetLume’s comprehensive suite of tools and features ensures that businesses are well-equipped to navigate the complexities of modern manufacturing and stay ahead in a competitive landscape.

If you’re ready to revolutionize your manufacturing processes with cutting-edge Industrial IoT solutions, contact NetLume today. Let us help you harness the power of digital twin technology to drive your business forward.

Conclusion

The rise of digital twin technology is a game-changer for the manufacturing sector, offering numerous benefits from predictive maintenance to enhanced product quality. NetLume, with its advanced IoT platform, provides the tools and capabilities necessary to implement and scale digital twin solutions effectively. By partnering with NetLume, manufacturers can unlock new levels of efficiency, innovation, and profitability, paving the way for a more connected and intelligent industrial future.