In an era where industries are evolving towards smart and autonomous solutions, fuel management stands at the forefront of innovation. The traditional challenges associated with tracking fuel quantities in storage tanks are now being overcome by cutting-edge technologies, particularly those powered by the Internet of Things (IoT). NetLume, a trailblazer in the IoT landscape, has introduced a game-changing solution for fuel inventory management, significantly enhancing efficiency and profitability for manufacturing facilities.

The Fuel Inventory Revolution

A Paradigm Shift with IoT-Powered Level Monitoring

Fuel inventory management has historically been a complex task, prone to inefficiencies and inaccuracies when relying on traditional methods. However, with NetLume’s advanced level monitoring solution, based on IoT principles, the landscape is transforming. The platform seamlessly integrates sensor-based inventory monitoring, real-time analytics, and automated tasks to provide manufacturing facilities with unparalleled control over their fuel inventories.

Key Features Driving Efficiency

- Smart Sensor-Based Inventory Monitoring

NetLume’s solution leverages intelligent sensors that communicate data to cloud-based digital dashboards. This real-time monitoring not only tracks fuel levels but also triggers automated actions such as scheduling tank refills or providing early warnings in case of safety concerns. The result is a proactive approach to inventory management, minimizing downtime and optimizing transportation. - Cost-Effective Operation with Reduced Overheads

IoT technology, as implemented by NetLume, acts as a catalyst for cost reduction in the fuel industry. By predicting maintenance needs and eliminating unidentified inefficiencies, the platform contributes to the longevity of storage tanks and reduces overall maintenance costs. The data-driven approach ensures that every decision is optimized for efficiency, ultimately boosting the profitability of fuel inventories. - Streamlined Automation for Increased Productivity

Gone are the days of labor-intensive manual processes. NetLume’s IoT-based solution automates critical industrial functions, from data management to plant operations. This not only speeds up processes but also minimizes the risk of errors and excessive fuel consumption. Managers can now maintain real-time visibility into fuel inventories without the need for additional staffing, leading to increased operational efficiency. - Digital Twin for Enhanced Asset Management

NetLume introduces a digital twin, a powerful tool that goes beyond conventional asset management. By predicting maintenance issues and optimizing operating parameters, the digital twin extends the life of assets and reduces downtime. The ability to compare performance across assets and conduct root-cause analyses empowers managers with evidence-based decision-making, ensuring optimal fuel usage and efficiency. - Comprehensive Operations Monitoring

Incorporating advanced sensors in oil fields, NetLume’s IoT solution continuously analyzes oil composition, providing detailed insights through reports. Statistical models estimate flow rates and composition, enhancing planning and fuel usage for production. The result is a holistic approach to operations monitoring that significantly contributes to the efficiency of fuel inventories.

NetLume: Empowering Manufacturing Excellence

Beyond fuel inventory management, NetLume stands as a beacon of innovation in the manufacturing sector. The platform’s no-code to low-code interface allows manufacturing facilities to design intricate domain models effortlessly. Through a drag-and-drop approach, factories can define components, connect them seamlessly, and configure data connectors for streamlined analytics.

Advantages for Manufacturing with NetLume

- Rapid Prototyping and Design

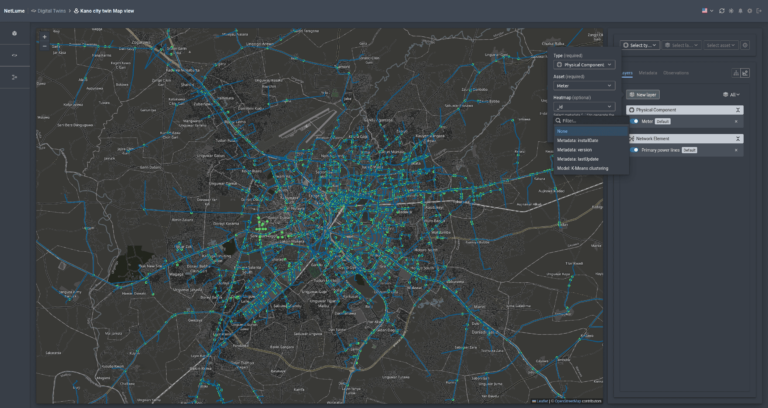

NetLume empowers manufacturing facilities with rapid prototyping capabilities, enabling quick and efficient design iterations. The intuitive drag-and-drop interface facilitates the seamless creation of domain models, ensuring that the manufacturing process is both agile and adaptive to changing requirements. - Real-Time Monitoring and Visualization

Manufacturers benefit from NetLume’s highly customizable map visualization, offering real-time insights into their entire network of assets. By connecting AI models to the map visualization, facilities can make data-driven decisions, optimize operations, and enhance overall efficiency. - Automated Lifecycle Management

NetLume simplifies and unifies the lifecycle management of connected solutions. Manufacturing facilities can automate tasks, ensuring that every aspect of their operations is efficiently monitored and managed. This unified approach reduces complexity and minimizes the risk of errors, contributing to enhanced productivity. - Low-Code to No-Code AI Model Design

NetLume’s interface allows manufacturing facilities to design AI models and data pipelines with ease. From low-code to no-code, the platform accommodates varying levels of technical expertise, democratizing the deployment of advanced analytics within the manufacturing domain.

Conclusion: NetLume – Pioneering Efficiency Across Industries

NetLume’s IoT leadership extends beyond fuel inventory management, permeating the manufacturing sector with groundbreaking solutions. By harnessing the power of IoT, NetLume empowers manufacturing facilities to achieve unparalleled efficiency, from rapid prototyping and real-time monitoring to automated lifecycle management and AI model design. As industries continue to embrace smart and connected technologies, NetLume remains at the forefront, driving innovation and efficiency across diverse domains.