In the ever-evolving landscape of industrial operations, the transition from traditional scheduled maintenance to predictive maintenance has become a pivotal turning point for companies seeking to maximize efficiency, minimize downtime, and optimize resource allocation. At the forefront of this transformative shift is NetLume, a cutting-edge All-In-One Data platform for AI applications and Industrial IoT.

Unveiling the Shift: Scheduled vs. Predictive Maintenance

The conventional approach of scheduled maintenance involves pre-designed inspection regimes that often necessitate industry-wide shutdowns, affecting productivity and consuming valuable resources. While scheduled maintenance is effective in preventing reactive repairs, its drawbacks in terms of operational disruption and resource allocation inefficiencies are undeniable.

On the other hand, predictive maintenance emerges as a proactive strategy that foresees equipment deterioration and conducts repairs just before performance decline. This transformative approach relies on real-time data analysis, enabling companies to predict and address potential breakdowns without the need for widespread shutdowns.

The IoT Paradigm: Enabling Predictive Maintenance

At the heart of this industrial metamorphosis is the Internet of Things (IoT), a technology that acts as a catalyst for predictive maintenance. IoT leverages advanced sensor devices to collect crucial data about equipment performance, which is then processed and analyzed through sophisticated cloud platforms. This real-time data allows for the early detection of potential issues, empowering operators to take proactive measures.

NetLume’s Distinctive Contribution

In the realm of IoT-driven predictive maintenance, NetLume stands out as a pioneer and leader. The platform’s All-In-One Data solution offers a seamless transition from scheduled to predictive maintenance with its innovative features and user-friendly interface.

1. Rapid Prototyping and No-Code Design

NetLume enables users to design their domain models with unparalleled ease through a no-code, drag-and-drop approach. Whether modeling an electricity grid or a factory setup, users can swiftly define components, interconnections, and data sources without the need for extensive coding expertise.

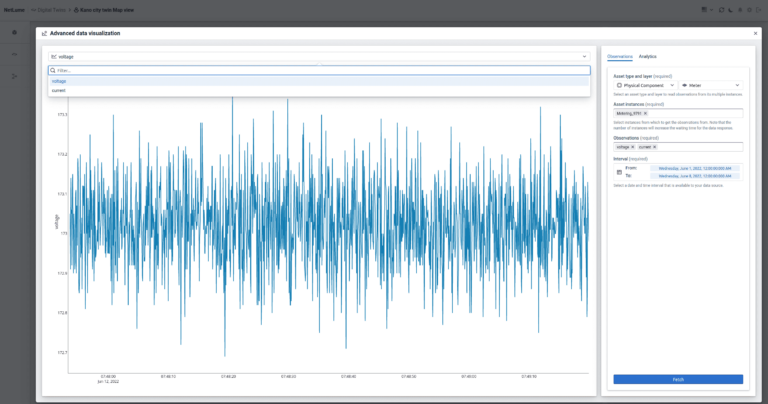

2. Real-Time Monitoring and AI Integration

The platform provides a highly customizable map visualization for real-time network monitoring. Users can connect AI models directly to this visualization, creating a dynamic and responsive system that adapts to evolving conditions. This integration enhances the ability to predict and address potential maintenance issues promptly.

3. Customizable Dashboards and Automated Reporting

NetLume empowers users with the creation of custom dashboards using a rich library of visualizations. Automated report generation and notifications further streamline the monitoring process, ensuring that relevant stakeholders are informed promptly about critical insights and maintenance requirements.

4. Unified Life-Cycle Management

NetLume simplifies and unifies the life-cycle management of connected solutions. From AI models deployment to data pipelines, the platform automates and streamlines processes, reducing manual intervention and enhancing overall operational efficiency.

5. Low-Code to No-Code Interface

NetLume’s interface offers a complete spectrum from low-code to no-code, allowing users to design AI models and data pipelines effortlessly. This flexibility ensures that both experienced data scientists and those with limited coding knowledge can contribute to the predictive maintenance journey.

The Future with NetLume and IoT

As industries increasingly recognize the value of predictive maintenance in reducing downtime and operational costs, the role of IoT, facilitated by platforms like NetLume, becomes even more crucial. Predictive maintenance, powered by IoT, is projected to grow significantly, and NetLume is poised to be a key player in this transformative journey.

In essence, NetLume’s innovative approach not only facilitates the transition from scheduled to predictive maintenance but also propels industries into a future where operational efficiency, cost-effectiveness, and machine reliability are paramount. Embrace the future with NetLume and witness a new era of industrial maintenance powered by IoT innovation.