In an era dominated by technological innovation, the manufacturing sector stands at the forefront of a transformative revolution, propelled by the rise of Digital Twin technology. Digital Twins, virtual replicas of physical objects or processes, have emerged as a game-changer in industrial IoT (Internet of Things), offering unprecedented insights, efficiency, and cost savings. As the manufacturing industry increasingly adopts this cutting-edge technology, NetLume, a pioneering force in the IoT domain, plays a pivotal role in shaping the future of industrial operations.

The Digital Twin Revolution:

Digital Twin technology is not merely a buzzword; it represents a paradigm shift in how industries conceptualize, monitor, and optimize their processes. At its core, a Digital Twin is a dynamic, data-driven replica of a physical entity, seamlessly blending the virtual and physical realms. In the manufacturing sector, this innovation is revolutionizing the way companies operate, reducing costs, enhancing asset control, and minimizing downtime caused by equipment failures.

NetLume’s Unique Approach:

Amidst this digital transformation, NetLume stands out as a beacon of innovation. As an IoT leader, NetLume offers a comprehensive, all-in-one data platform tailored for AI applications and Industrial IoT. Unlike conventional solutions, NetLume empowers users with a low-code to no-code interface, facilitating the seamless design and deployment of AI models and data pipelines.

The NetLume Advantage:

1- Effortless Domain Modeling:

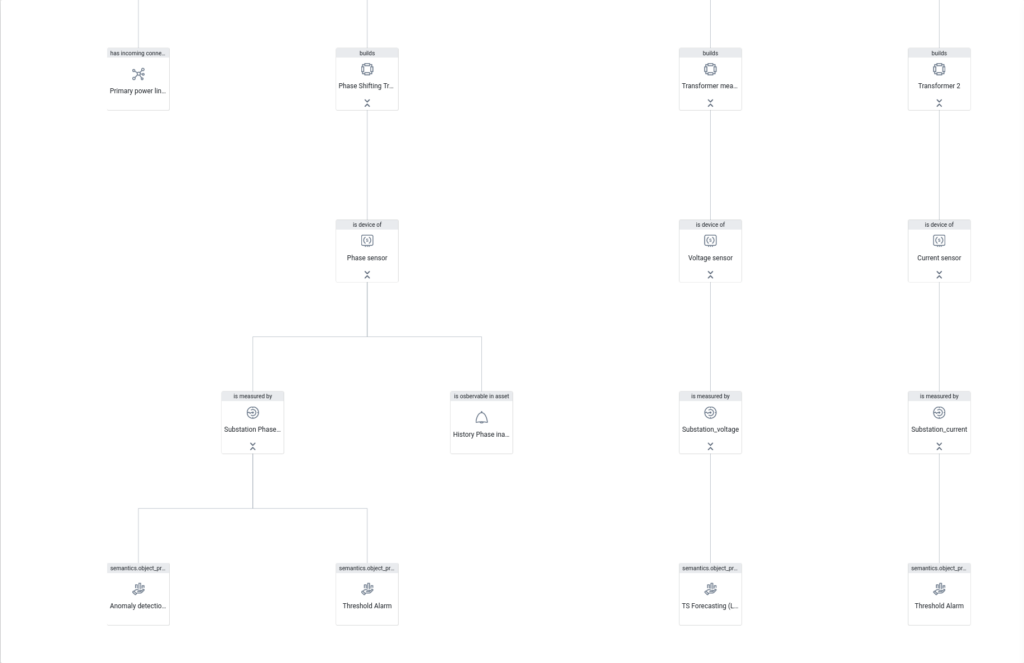

NetLume’s intuitive drag-and-drop interface allows users to effortlessly model their industrial domains, whether it’s an electricity grid or a manufacturing facility. This no-code approach simplifies the definition of components, connections, and data sources, streamlining the digital twin creation process.

2- Real-Time Insights:

Leveraging NetLume’s platform, companies can connect all their relevant data sources, deploy machine learning models, and gain real-time insights into their entire network. The highly customizable map visualization, coupled with real-time monitoring, provides a holistic view of assets and operations.

3- Low-Code AI Model Design:

NetLume redefines the creation of AI models with a low-code approach, allowing users to design and deploy analytics with just a few clicks. This not only accelerates the development process but also democratizes AI, enabling a broader range of stakeholders to contribute to data-driven decision-making.

The Role of Digital Twins in Manufacturing:

Digital Twins, particularly in manufacturing, offer multi-level benefits:

- Component Level: Focuses on critical individual components in the manufacturing process.

- Asset Level: Creates digital replicas of specific equipment used in production.

- System Level: Enhances the entire production line when improvements are needed.

- Process Level: Encompasses the entire life cycle of a product, from design to end-user usage.

The Digital Twin Workflow:

- Constructing:

Equipping physical objects with sensors and encoding operational and external data for secure transfer to digital replicas. - Aggregating:

Aggregating data into a warehouse/repository for analysis, whether on the cloud or on-premises. - Analyzing:

Employing advanced analytics platforms to generate actionable insights from the data. - Insight Stage:

Presenting insights through visual dashboards, highlighting disparities between the physical and digital realms. - Act:

Utilizing actionable insights to influence physical assets, ensuring intelligent decision-making and control.

NetLume’s Contribution to the Digital Twin Ecosystem:

NetLume seamlessly integrates into the Digital Twin workflow, providing a unified platform for domain modeling, data connection, AI model deployment, and real-time monitoring. The platform’s versatility, coupled with its user-friendly interface, positions NetLume as a catalyst for accelerating the adoption of Digital Twins in the manufacturing sector.

Cornerstones for Success with Digital Twins:

- Identifying Opportunities:

Envisioning areas within a manufacturing unit that can benefit from Digital Twin technology, focusing on crucial components and process-related challenges. - Detecting the Process:

Identifying pilot configurations with high value and success rates, considering organizational change management factors and operational interconnections. - Start Narrow:

Beginning with a limited scope pilot to demonstrate value, with a focus on adaptability and integration with diverse data sources. - Expanding the Pilot:

Scaling successful pilots and identifying opportunities for broader implementation, learning from initial mistakes, and communicating value to stakeholders. - Continuous Evaluation:

Monitoring and measuring solutions post-implementation, making iterative adjustments, and refining the Digital Twin process for optimal configuration.

Conclusion:

As the manufacturing industry undergoes a digital transformation propelled by the rise of Digital Twins, NetLume emerges as a key player, facilitating a seamless and innovative journey into the realm of industrial IoT. Through its user-friendly platform, NetLume empowers industries to embrace the future of manufacturing, where Digital Twins become indispensable for achieving efficiency, reducing costs, and delivering unparalleled insights. Embrace the Digital Twin revolution with NetLume and redefine the way you envision, monitor, and optimize your industrial processes.