The manufacturing landscape is evolving at an unprecedented pace, driven by the digital transformation of factories into smart manufacturing hubs. Smart factories, enabled by the Internet of Things (IoT), are redefining the way we produce goods and manage operations. In this comprehensive article, we’ll explore the significance of smart factory IoT in manufacturing and how NetLume, a pioneering IoT leader, is revolutionizing this industry.

The Smart Factory Revolution

A smart factory is a digitized manufacturing facility that leverages IoT, connected devices, and advanced production systems to collect, analyze, and share data continuously. These data-driven insights are harnessed to optimize processes, enhance decision-making, and address issues in real-time. The impact of smart factories on the manufacturing industry is profound and multifaceted.

- Data-Driven Decision-Making: Smart manufacturing allows factory managers to automatically collect and analyze data to make informed decisions and optimize production. This data is generated by sensors and machines, which communicate with the cloud through IoT connectivity solutions.

- Growth of IoT in Manufacturing: According to research by Mordor Intelligence, the IoT market in manufacturing is growing rapidly, with a projected CAGR of 14.76%. Manufacturers are increasingly adopting IoT to enhance traceability, transparency, and operational efficiency.

Common Smart Factory Technologies

Smart factories are characterized by a high degree of automation, driven by a range of industrial IoT technologies. These technologies include:

- Cloud Computing: Cloud platforms like AWS and Azure enable secure data processing, storage, and analysis at scale.

- Big Data: Big data technologies are used for the continuous collection, storage, and analysis of production-related data, enabling insights and predictive analytics.

- RFID and QR Code: These technologies aid in tracking industrial equipment, inventory, finished goods, and workers, enhancing transparency and efficiency.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are employed for end-to-end automation, equipment monitoring, and advanced analytics insights, such as predictive maintenance.

IoT Use Cases in Manufacturing

IoT has numerous applications in smart factories, and several use cases have demonstrated its effectiveness:

- Remote Monitoring of Production: Sensors enable remote monitoring of equipment and production rates, optimizing input-output ratios.

- Supply Chain Management: IoT enhances supply chain efficiency through real-time tracking, warehouse automation, digital paperwork management, and improved inventory control.

- Quality Control: Automation and sensors, including thermal imaging, are used to systematize quality control inspections and ensure product consistency.

- Predictive Maintenance: Vibration and humidity sensors, among others, provide data for predictive maintenance, reducing downtime and production disruptions.

NetLume’s Role in Smart Factory IoT

NetLume is at the forefront of the smart factory IoT revolution, offering a powerful and unique platform to drive digital transformation in manufacturing. Here’s how NetLume is changing the game:

- Global Connectivity: By connecting factories worldwide in the cloud, NetLume strengthens the global production system. It enables real-time analysis and the ability to respond immediately to production changes based on local demand.

- Digital Transformation: NetLume empowers technical engineers to incorporate digital power into physical improvement activities, accelerating gains in efficiency, quality, and cost savings. It connects various devices to notify operators of equipment abnormalities, reducing downtime.

- Traceability: NetLume enhances traceability, making it easier to track the movement of workers and the operation status of different facilities.

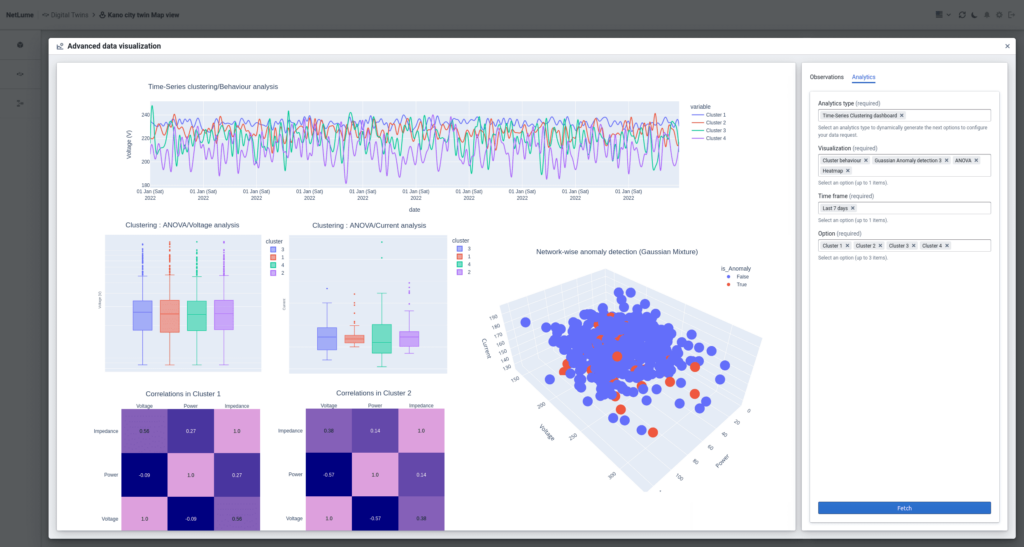

- Data Analysis: The platform offers advanced data analysis tools, enabling manufacturers to harness the power of data-driven decision-making.

- Quality Control: NetLume facilitates automated quality control, ensuring product consistency across the board.

- Facility Operation Management: It streamlines facility operations, optimizing resource allocation and improving overall efficiency.

- Digitalization of Paper Forms: NetLume’s digitalization capabilities eliminate paperwork and enhance data accuracy.

Conclusion

The future of manufacturing belongs to smart factories, and the role of IoT in this transformation is undeniable. With NetLume leading the way, manufacturers can harness the power of IoT to streamline operations, enhance productivity, and make data-driven decisions in real-time. As the manufacturing industry continues to evolve, embracing smart factory IoT is not just an option; it’s a necessity for staying competitive in the global market. NetLume’s innovative solutions are poised to reshape the future of manufacturing, making it smarter, more efficient, and more connected than ever before.