In an era where manufacturing efficiency is a make-or-break factor for businesses, harnessing the potential of advanced Internet of Things (IoT) energy insights sensors is no longer just an option; it’s a strategic necessity. These sensors are not only driving immediate cost savings but are also shaping the future of manufacturing. This article explores the transformative power of smart sensors and how NetLume, an IoT leader, is at the forefront of this manufacturing revolution.

1. Enhanced Visibility for Unprecedented Efficiency

Smart sensors represent a paradigm shift in manufacturing. They provide a real-time, 360-degree view of your entire operation. By attaching wireless IoT sensors to your energy-intensive assets at a circuit level, you gain granular insights into your power usage, gas, heat, air flow, and water consumption. This level of detail enables you to identify energy waste and inefficiencies that would have otherwise remained hidden, paving the way for substantial cost savings.

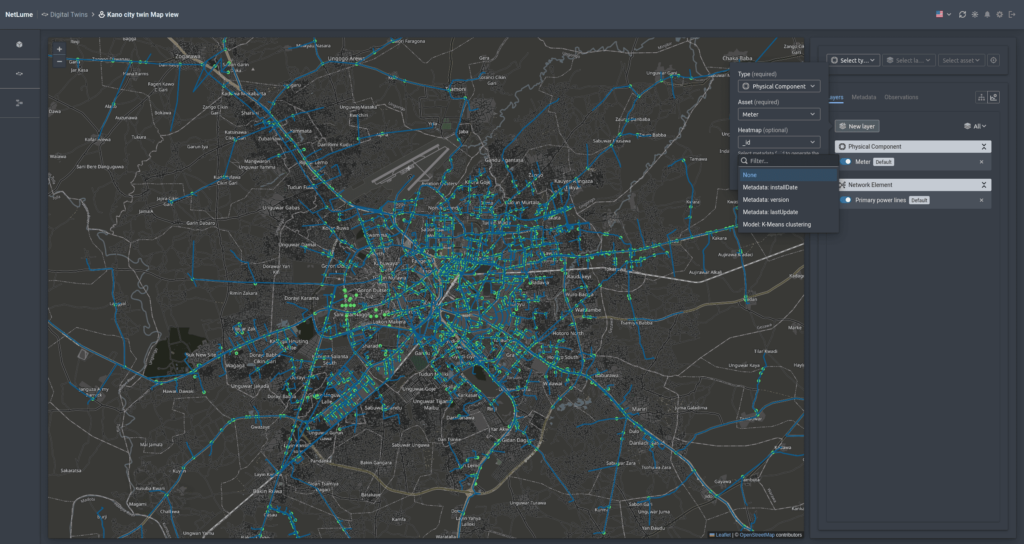

2. The NetLume Advantage: Unparalleled Domain Modeling

NetLume offers an innovative approach to manufacturing efficiency. Their All-In-One Data platform empowers businesses to model their domains seamlessly. Whether it’s an electricity grid, a production line, or a complex manufacturing facility, NetLume allows you to define all components with a drag-and-drop, no-code approach. This means you can effortlessly configure connectors to ingest data and deploy analytics, all while ensuring that every aspect of your operation is optimized.

3. Unleashing Operational Efficiency

The insights provided by smart sensors extend far beyond energy efficiency. By having on-demand access to real-time equipment and process performance data, manufacturers can make data-driven decisions that drive operational improvements. Whether it’s identifying air leaks, diagnosing performance issues, or optimizing equipment controls, the resulting cost savings can be substantial.

4. Preventing Equipment Failure with Predictive Maintenance

Smart technology also plays a pivotal role in predictive maintenance. By analyzing data from IoT sensors, anomalies, and faulty equipment can be detected early. This proactive approach reduces downtime, increases productivity, and extends the lifespan of assets, ultimately contributing to significant cost savings.

5. Driving Environmental Sustainability

Manufacturers today not only focus on the bottom line but also on their environmental impact. By enhancing energy and operational efficiency, companies are effectively reducing their carbon footprint. This not only aligns with sustainability expectations but also positions businesses to meet environmental regulations and carbon taxation requirements.

6. Simplifying Compliance and Reporting

Smart sensors, when combined with NetLume’s comprehensive data platform, simplify compliance and reporting. Accurate data is readily available to support regulatory oversight and environmental reporting, ensuring that businesses can easily meet obligations like the Energy Savings Opportunity Scheme (ESOS) or Streamlined Energy and Carbon Reporting (SECR).

7. Monetizing Energy Flexibility for the Future

Smart sensors open up new avenues for optimizing and monetizing energy flexibility. With the data collected, manufacturers can identify opportunities to shift loads and avoid peak-time power costs. They can also participate in Demand Side Response (DSR) activities and tap into other trading opportunities, creating additional revenue streams.

NetLume, with its no-code to low-code interface, positions businesses to fully leverage the potential of smart sensors. Their platform allows for easy domain modeling, AI model deployment, and real-time network monitoring. By providing a unified and simplified lifecycle management for all connected solutions, NetLume streamlines the path to manufacturing efficiency and sustainability.

In a world where manufacturing efficiency is paramount, the role of smart sensors and IoT solutions cannot be overstated. These technologies are reshaping the industry landscape, driving cost savings, enhancing sustainability, and paving the way for a more efficient and profitable future. With NetLume at the forefront of this revolution, manufacturers are well-equipped to thrive in an increasingly competitive and environmentally-conscious world.