In today’s rapidly evolving industrial landscape, asset monitoring and predictive maintenance have become pivotal components for ensuring the seamless operation of complex systems across various sectors, such as mining operations, wind and solar farms, construction sites, and manufacturing facilities. As industries rely increasingly on robust, secure, and cost-effective IoT connectivity, the need for real-time insights and predictive capabilities has never been greater. This article explores the significance of IoT in asset monitoring and predictive maintenance and how NetLume, a leading IoT company, can provide innovative solutions to address these challenges.

Asset Monitoring: A Crucial Element in Modern Industries

Asset monitoring, in its essence, is the practice of remotely tracking the location and condition of equipment, machinery, and other valuable assets within industrial settings. This practice has witnessed significant growth with the rise of the Internet of Things (IoT), as it enables real-time tracking and monitoring of assets across various industries.

How Asset Monitoring Works

At the heart of asset monitoring lies the use of sensors. These sensors measure a range of parameters, from location and speed to temperature and vibrations, depending on the specific application. The data collected by these sensors is then transmitted to a cloud solution or processed at the network edge, allowing remote teams to monitor assets in near real-time. This data can be further leveraged with AI and machine learning capabilities to facilitate automated decision-making processes.

The Need for Asset Monitoring

The necessity for asset monitoring is widespread, spanning across industries that rely on complex machinery and systems. In manufacturing, for instance, asset monitoring and predictive maintenance have the potential to reduce unplanned downtime. This is particularly important since unplanned downtime can be up to ten times more costly than planned maintenance.

In the wind energy sector, asset monitoring is essential as well. The Global Wind Energy Council reported a 53 percent increase in new wind capacity in 2020. With over 60 percent of land-based turbine operation and maintenance costs being attributed to unscheduled downtime, monitoring these complex systems becomes imperative.

Real-World Success Stories: Asset Monitoring in Action

One compelling example of asset monitoring in action comes from Eaton, a power management company. Eaton collaborated with Digi, an industry leader in IoT solutions, to develop a predictive monitoring system. This system effectively predicts hydraulic hose failure, helping Eaton avoid costly unscheduled repairs and providing enhanced visibility into customer assets.

Asset Tracking: Streamlining Operations

Asset tracking, while closely related to asset monitoring, serves a slightly different purpose. It allows companies to keep a close eye on high-value equipment in real-time, tracking their location, usage, and handling. This is particularly beneficial for industries that manage large volumes of equipment, like construction and farming operations.

Asset Tracking Use Cases

Asset tracking and monitoring have a multitude of applications, including:

- Integrating GPS into products and equipment for precise asset tracking.

- Improving the efficiency of production lines, distribution processes, and transportation routes.

- Enhancing predictive maintenance by analyzing patterns identified through data collection.

- Providing critical asset monitoring for high-value and mission-critical assets via IoT connectivity and management software.

Asset Management: Beyond Tracking

Asset management goes beyond tracking and location monitoring; it encompasses the overall software systems that control information about assets. This includes maintenance schedules, audits, purchase information, end-of-life equipment disposal, and more. In essence, it is about efficiently managing assets throughout their lifecycle.

Choosing the Right Technologies

A range of technologies supports asset monitoring and management, including:

- Radio Frequency Identification (RFID).

- Global Positioning System (GPS).

- Barcode technology.

- Bluetooth Low Energy (BLE).

- Near Field Communication (NFC).

IoT Asset Monitoring Benefits

The Internet of Things enables smart asset monitoring and remote inspections, significantly reducing the need for on-site visits. With IoT sensors capable of measuring almost any aspect of a system, asset management applications can use this data for predictive maintenance, which ultimately increases system reliability and significantly reduces costs associated with unplanned failures.

Predictive Maintenance: A Game-Changer

Predictive maintenance is a critical part of IoT asset monitoring, relying on sensors and intelligent edge devices to identify anomalies and predict system failures before they happen. It uses real-time data analysis to schedule maintenance around production schedules, reducing costs and enhancing customer satisfaction.

How Predictive Maintenance Works

Predictive maintenance technology continuously monitors equipment status and performance, analyzing sensor data to identify potential problems. Operators receive alerts about these issues, allowing for proactive preventive maintenance. The application of AI and machine learning further enhances the effectiveness of predictive maintenance.

Real-World Examples of Predictive Maintenance

The renewable energy sector offers a prime example of the importance of predictive maintenance. The reliability of wind and solar energy systems is crucial as they contribute significantly to the power grid. Predictive maintenance helps avoid production outages and reduces costs. For instance, the U.S. Department of Energy states that predictive maintenance can result in savings of up to 40 percent over reactive maintenance.

Otis, a global leader in elevator manufacturing, utilizes IoT solutions for predictive maintenance. By proactively detecting potential issues, Otis ensures optimal customer service, preventing elevator service disruptions and enhancing customer experiences.

Predictive Maintenance in Various Industries

Predictive maintenance isn’t limited to one sector. It plays a significant role in:

- Manufacturing, improving quality, uptime, and worker safety.

- The railway sector, detecting problems with assets and tracking irregularities.

- The oil and gas industry, allowing maintenance in remote locations.

- Mining operations, saving millions by avoiding unexpected equipment failures.

Preventative vs. Predictive Maintenance: Finding the Balance

Both preventative and predictive maintenance are proactive approaches to maintenance, but they differ in their schedules. Preventative maintenance is scheduled and routine, while predictive maintenance is based on asset condition monitoring and anomaly detection. A combination of both approaches is often the most effective way to reduce unplanned downtime.

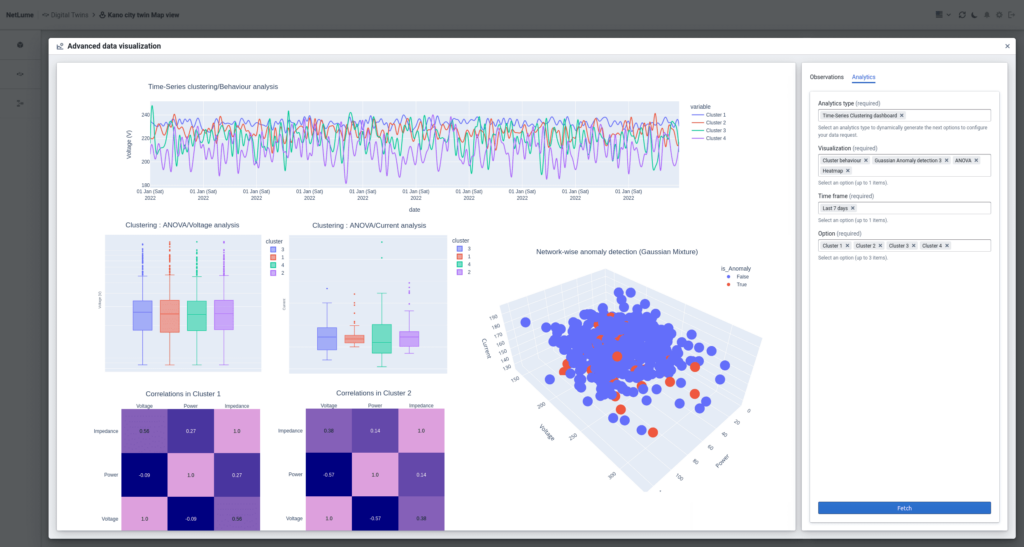

NetLume: Leading the IoT Revolution

In the realm of IoT, NetLume stands as a pioneering force, providing innovative solutions for asset monitoring and predictive maintenance. NetLume offers an all-in-one data platform for AI applications and Industrial IoT, allowing industries to model their domains, connect data, and deploy machine learning models for real-time insights.

NetLume’s benefits include rapid prototyping, real-time monitoring, customizable dashboards, automated life-cycle management, and a low-code to no-code interface for designing AI models and data pipelines. The platform empowers industries to harness the potential of IoT in asset monitoring and predictive maintenance, ensuring uninterrupted operations and cost savings.

Conclusion: The Future of Asset Monitoring and Predictive Maintenance

The future of asset monitoring and predictive maintenance is bright, with IoT playing a pivotal role in enhancing the efficiency and reliability of industrial systems. As businesses across various sectors seek to minimize unplanned downtime, reduce maintenance costs, and optimize their operations, the importance of embracing IoT solutions cannot be overstated. NetLume, as a leading IoT company, is at the forefront of this technological revolution, offering cutting-edge solutions to meet the challenges of the future. With NetLume’s expertise and innovation, industries can look forward to a future of uninterrupted operations and enhanced productivity.