The oil and gas industry has always been at the forefront of innovation, constantly evolving to adapt to the changing global landscape. With fluctuating oil prices, increasing environmental regulations, and an aging workforce, the industry has faced a series of challenges. In this dynamic environment, the Internet of Things (IoT) has emerged as a transformative force, offering new solutions to age-old problems. This article explores the significance of IoT in the oil and gas sector and the pivotal role played by industry leaders like NetLume.

The Internet of Things in the Oil and Gas Industry

IoT, often referred to as the “fourth industrial revolution,” is a technological paradigm that revolves around connecting everyday objects and devices to the internet. The oil and gas industry is no exception, as IoT has the potential to revolutionize every aspect of its operations.

- Data Acquisition and Analysis: IoT-enabled sensors are strategically placed throughout oil fields and pipelines to monitor various parameters, such as flow rates, temperature, and pressure. This real-time data is then analyzed to detect anomalies and improve exploration and drilling operations.

- Drilling Optimization: IoT devices play a crucial role in optimizing drilling operations. They provide real-time data on drilling parameters, allowing for instant adjustments to enhance efficiency. Predictive maintenance also helps identify equipment issues before they cause downtime.

- Production Tracking and Optimization: Continuous monitoring of well performance enables the identification of optimization opportunities, resulting in increased efficiency. Automated control systems adjust production processes in real time, reducing operating costs.

- Pipeline Monitoring and Maintenance: Sensors monitor pipeline conditions, facilitating real-time leak detection and prevention. Early warning systems provide immediate alerts, minimizing environmental impact.

- Energy Consumption Optimization: IoT optimizes energy usage by monitoring and controlling pumping systems. Integration with renewable energy sources reduces reliance on fossil fuels, while data analytics enable efficient energy management.

- Refining and Processing: Real-time monitoring of process variables improves efficiency and productivity. Predictive maintenance minimizes downtime and extends equipment lifespan, contributing to cost savings.

- Safety and Environmental Monitoring: IoT ensures compliance with safety and environmental regulations by monitoring and detecting hazardous conditions. Real-time alerts in emergency situations enhance safety measures.

- Logistics and Distribution: Real-time location tracking optimizes routing and asset utilization. IoT-enabled systems enhance inventory management, improve logistics planning, and reduce delays.

Challenges in the Oil and Gas Industry

The oil and gas industry faces several challenges, including:

- Equipment Monitoring and Maintenance: Monitoring the health and performance of critical equipment, especially in remote locations, is a significant challenge.

- Environmental Monitoring: Detecting gas leaks, monitoring air and water quality, and measuring noise levels are essential for environmental compliance and safety.

- Supply Chain Complexity: Managing complex supply chains with numerous stakeholders requires efficient coordination and real-time data sharing.

- Inventory Management: Efficiently tracking the movement of assets, materials, and products is crucial for logistics planning and reducing delays.

The Role of IoT in Overcoming Challenges

IoT offers solutions to these challenges:

- Remote Monitoring & Control: IoT devices enable real-time monitoring of equipment and environmental conditions. Operators can identify issues, take preventive actions, and optimize operations.

- Predictive Maintenance: IoT sensors continuously monitor equipment parameters, allowing for predictive maintenance that reduces downtime and extends equipment lifespan.

- Safety & Emergency Response: IoT ensures worker safety by detecting hazardous conditions and providing real-time alerts in emergencies.

- Environmental Monitoring & Compliance: IoT sensors monitor environmental parameters, ensuring compliance with regulations and enabling corrective actions in case of incidents.

NetLume: Leading the IoT Revolution in Oil and Gas

NetLume is at the forefront of the IoT revolution in the oil and gas industry. As an All-In-One Data platform for AI applications and Industrial IoT, NetLume offers a comprehensive solution that addresses the unique needs of the sector.

- Domain Modeling: NetLume’s platform allows users to model their specific domains, from oil fields to pipelines, with a user-friendly drag-and-drop interface.

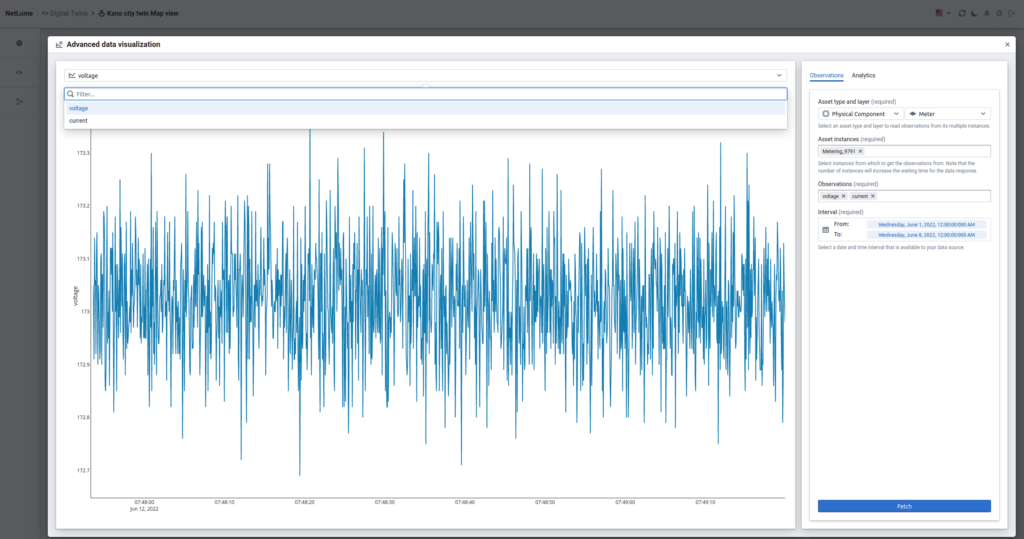

- Real-Time Monitoring: With highly customizable map visualization, NetLume provides real-time monitoring of assets, enabling informed decision-making.

- AI Integration: The platform supports the deployment of AI models, providing insights and predictive analytics to enhance operational efficiency.

- Custom Dashboard Design: Users can create custom dashboards with a rich library of visualizations, automated report generation, and notifications.

- Low-Code to No-Code: NetLume’s low-code to no-code interface simplifies AI model design and data pipeline creation.

The Future of IoT in Oil and Gas

As the oil and gas industry embraces IoT, the future looks promising. Real-time data analysis, predictive maintenance, and optimized operations will become the norm, leading to increased efficiency, reduced costs, and enhanced safety. By leveraging IoT technologies, organizations can overcome challenges, ensure compliance, and improve environmental sustainability.

In conclusion, IoT is a game-changer for the oil and gas industry, and NetLume is a key player in this transformation. With its comprehensive platform and expertise, NetLume empowers the industry to harness the full potential of IoT, ensuring a brighter and more sustainable future for oil and gas operations.