Manufacturing, often referred to as the backbone of the global economy, has been undergoing a significant transformation, driven by the convergence of technology and innovation. At the heart of this transformation is the Internet of Things (IoT), a revolutionary concept that is reshaping the way we design, produce, and manage products. In this comprehensive article, we will explore the symbiotic relationship between manufacturing and IoT, delve into its importance for the future, and highlight the pivotal role played by IoT leaders like NetLume.

The Manufacturing and IoT Partnership:

Manufacturing, characterized by its reliance on complex processes and large-scale production, has long been searching for ways to enhance efficiency, reduce costs, and improve overall productivity. The IoT, on the other hand, is a network of interconnected devices, sensors, and systems that collect and exchange data. This technology is revolutionizing manufacturing in several ways:

Rapid Prototyping: The IoT enables manufacturers to rapidly prototype their assets and systems, allowing for quick adjustments and optimizations during the design phase. This significantly reduces time-to-market for new products.

Real-Time Monitoring: IoT provides real-time monitoring of manufacturing processes, which leads to optimized production flows, reduced waste, and lower work-in-process inventory. Manufacturers can identify inefficiencies and make immediate adjustments.

Predictive Maintenance: IoT sensors can monitor the health and performance of manufacturing equipment, predicting maintenance needs before they cause costly downtime. This proactive approach helps reduce operational disruptions.

Supply Chain Optimization: IoT solutions track the movement of vehicles and assets in the supply chain, leading to improved efficiency in manufacturing and logistics operations.

Quality Control: IoT sensors capture data on product specifications and quality metrics, enhancing quality control processes and ensuring that products meet high standards.

Warehouse Management: IoT simplifies warehouse management, helping manufacturers keep track of inventory, reduce losses, and improve overall logistics.

Operational Intelligence: Autonomous machinery and IoT-connected devices create intelligent networks that can communicate and coordinate, reducing human intervention and improving overall production efficiency.

The Importance of IoT in Manufacturing:

The adoption of IoT in manufacturing is no longer a luxury but a necessity. Industry 4.0, characterized by technological advancements and innovative tools, is driving transformative IoT use cases that promise substantial returns on investment. Here’s why IoT is so important for the manufacturing industry:

- Efficiency and Productivity: The manufacturing sector is under constant pressure to increase efficiency and productivity while reducing costs. IoT optimizes production processes, minimizes downtime, and streamlines operations.

- Predictive Maintenance: IoT sensors help manufacturers avoid equipment failures and downtime by collecting and analyzing data in real time to identify potential issues before they disrupt operations.

- Streamlining Asset Tracking: IoT simplifies asset tracking, reducing the risk of lost or damaged assets and minimizing costs associated with tracking.

Quality Control: IoT sensors monitor critical parameters like humidity, temperature, and air quality, helping manufacturers meet quality standards and improve product quality.

- Warehouse Management: IoT solutions optimize logistics, reducing shipping costs, minimizing damage, and improving overall efficiency in the supply chain.

IoT Trends in Manufacturing for 2023:

As we look to the future, several IoT trends are set to reshape the manufacturing landscape:

Employee Safety: IoT sensors and wearables can track vital signs and environmental conditions, enhancing safety for workers and preventing accidents.

Security and Privacy: As IoT becomes more prevalent in manufacturing, security and privacy become paramount, with a focus on risk assessments, encryption, and data protection.

- Machine-to-Machine (M2M) Automation: IoT-enabled devices can communicate and automate tasks, reducing the need for human intervention in various manufacturing processes.

IoT with Virtual and Augmented Reality (VR/AR): IoT data can be combined with VR and AR to create immersive experiences for training, equipment management, and process visualization.

NetLume’s Role in Manufacturing:

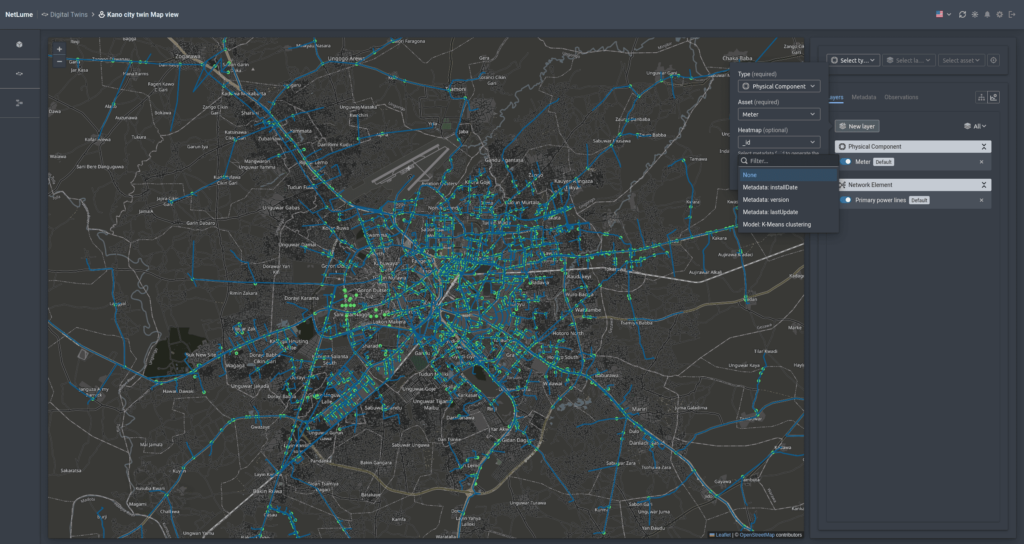

NetLume, as an IoT leader, plays a pivotal role in driving the transformation of the manufacturing industry. Their All-In-One Data platform for AI applications and Industrial IoT provides manufacturers with the tools and capabilities to fully leverage the potential of IoT in their operations. With features such as rapid prototyping, real-time monitoring, predictive maintenance, and quality control, NetLume empowers manufacturers to optimize their processes, reduce costs, and stay competitive in the ever-evolving manufacturing landscape.

Conclusion:

The partnership between manufacturing and IoT is shaping the future of industry. As manufacturers embrace IoT technologies, they gain a competitive edge through enhanced efficiency, predictive maintenance, streamlined logistics, and improved product quality. NetLume and other IoT leaders are at the forefront of this transformation, providing the necessary tools and platforms to drive manufacturing excellence. As we move into 2023 and beyond, the continued evolution of IoT in manufacturing promises to revolutionize the industry and pave the way for a more efficient, productive, and sustainable future.