In the realm of manufacturing, where efficiency, predictive maintenance, and seamless operations are paramount, a groundbreaking technology has emerged as a game-changer: the digital twin. Digital twins, virtual replicas of physical assets or systems, have ushered in a new era of industrial IoT (Internet of Things) applications, offering unprecedented insights and capabilities to businesses across the globe.

At the forefront of this revolution stands NetLume, a pioneering company specializing in All-In-One Data platforms tailored for AI applications and Industrial IoT. With a commitment to innovation and a focus on empowering industries, NetLume offers a comprehensive suite of tools and features designed to maximize the potential of digital twins in manufacturing sectors.

### Unveiling the Power of Digital Twins

Digital twins are more than just conceptual replicas; they represent a convergence of cutting-edge technologies, including sensors, AI, and data analytics, to create dynamic, real-time reflections of physical assets. These virtual counterparts enable manufacturers to:

– **Predictive Maintenance**: By continuously monitoring and analyzing data from sensors embedded in equipment, digital twins can anticipate potential issues before they escalate, minimizing downtime and optimizing maintenance schedules.

– **Operational Optimization**: Digital twins provide invaluable insights into the performance of manufacturing processes, allowing businesses to identify inefficiencies, streamline workflows, and enhance overall productivity.

– **Enhanced Decision-Making**: With access to a virtual representation of their assets, manufacturers can simulate various scenarios, assess the impact of different strategies, and make informed decisions to drive business growth.

### NetLume’s Innovative Approach

In the rapidly evolving landscape of industrial IoT, NetLume stands out for its commitment to simplicity, flexibility, and effectiveness. Here’s how NetLume revolutionizes the adoption of digital twins in manufacturing:

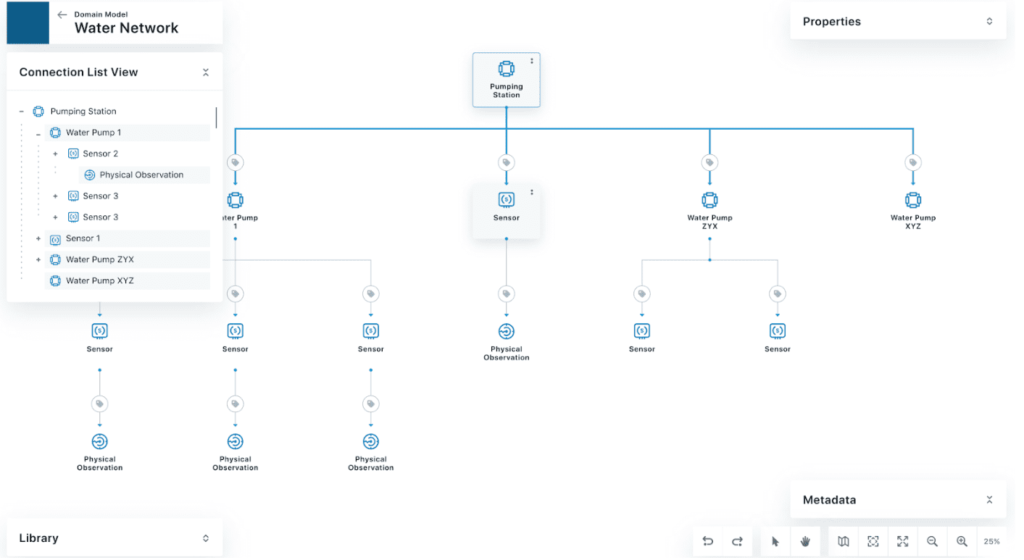

– **Intuitive Design Interface**: NetLume’s platform offers a user-friendly, drag-and-drop interface, allowing businesses to effortlessly model their assets and systems without the need for extensive coding or technical expertise. This streamlined approach accelerates the deployment of digital twins and empowers users to unleash the full potential of their data.

– **Real-Time Monitoring and Visualization**: With NetLume, manufacturers gain access to a highly customizable map visualization that provides real-time insights into their networks and assets. This interactive dashboard, coupled with advanced AI models, enables proactive decision-making and facilitates rapid response to changing conditions.

– **End-to-End Lifecycle Management**: NetLume simplifies the entire lifecycle management process for connected solutions, offering automated tools for deployment, monitoring, and optimization. From initial setup to ongoing maintenance, NetLume ensures seamless integration and maximum efficiency at every stage.

– **Scalable and Agile Solutions**: Whether you’re a small-scale operation or a global enterprise, NetLume’s platform is designed to scale effortlessly to meet your evolving needs. With a modular architecture and flexible deployment options, NetLume adapts to your requirements, enabling you to unlock new opportunities and stay ahead of the competition.

### Embracing the Future of Manufacturing

As the manufacturing industry continues to embrace digital transformation, the role of digital twins will become increasingly central to operations. By harnessing the power of NetLume’s innovative platform, businesses can unlock new levels of efficiency, agility, and profitability, paving the way for a smarter, more connected future.

In conclusion, the rise of digital twins in the manufacturing sector represents a paradigm shift in how industries approach asset management, optimization, and decision-making. With NetLume as their trusted partner, manufacturers can embark on this transformative journey with confidence, knowing that they have the tools, expertise, and support needed to thrive in the digital age.