In the ever-evolving landscape of industrial technology, the Internet of Things (IoT) has emerged as a transformative force, revolutionizing how businesses operate and optimize their processes. One of the industries benefiting significantly from IoT is oil and gas, where the integration of sensor-based systems provides unprecedented efficiency and control. In this article, we delve into the world of IoT-based Remote Oil & Diesel Tank Monitoring Systems, exploring the reasons behind its popularity and how NetLume, a leading All-In-One Data platform for AI applications and Industrial IoT, takes fuel management to new heights.

Why IoT for Oil and Diesel Tank Monitoring?

The IoT has become a cornerstone in industrial advancement, offering real-time applications and sensor-driven methodologies that enhance productivity. The oil and gas sector, recognizing the potential of IoT, has embraced this technology to streamline operations and ensure optimal performance. Here’s why IoT is the go-to solution for remote oil and diesel tank monitoring:

1- Remote Access:

- The IoT facilitates remote access to fuel tanks regardless of their location. With sensor-enabled technology, data is communicated through protocols to smart devices, allowing managers to monitor tanks from anywhere, anytime.

- NetLume, with its intuitive platform, extends this remote access capability, enabling seamless connectivity and control over fuel assets.

2- Advanced Analytics:

- IoT-enabled sensors extract relevant information from oil and diesel tanks, providing users with comprehensive data. This information undergoes advanced analytics, employing algorithms to generate insightful outcomes.

- NetLume enhances this analytical capability with a robust suite of tools, allowing for in-depth analysis and informed decision-making based on real-time data.

3- Predictive Maintenance:

- Leveraging IoT technology, businesses in the oil and gas sector can implement predictive maintenance strategies. This involves identifying asset flaws and conditions, predicting scheduled maintenance, and reducing operational costs.

- NetLume’s life-cycle management features complement this strategy, ensuring a unified and simplified approach to maintenance across connected solutions.

4- Real-time Monitoring:

- IoT’s real-time monitoring capabilities are instrumental in tracking fuel stock levels. Sensor devices installed on tanks provide accurate level updates to managers through interconnected smart gadgets.

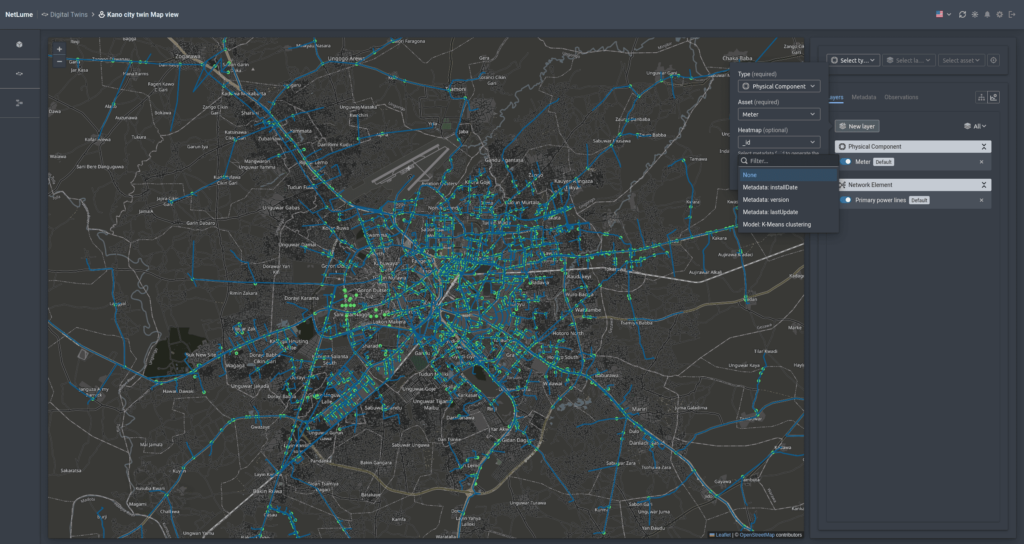

- NetLume takes real-time monitoring to the next level with customizable map visualizations, AI model integration, and a variety of visualizations on its platform, providing a comprehensive view of the industrial assets.

NetLume’s Contribution to IoT-Based Tank Monitoring:

As a frontrunner in the IoT landscape, NetLume offers a distinctive approach to remote oil and diesel tank monitoring. Here’s how

NetLume adds value to fuel management:

1- Intuitive Design:

- NetLume’s platform provides a user-friendly, no-code to low-code interface for designing AI models and data pipelines. Designing your domain model, whether for an electricity grid or a factory, is as easy as a drag-and-drop approach.

2- Rapid Prototyping:

- With NetLume, rapid drag-and-drop prototyping of assets and systems becomes effortless. Whether configuring connectors or deploying analytics, NetLume accelerates the development process, saving valuable time for businesses.

3- Custom Dashboard and Visualization:

- NetLume empowers users to design custom dashboards with a rich library of visualizations. The platform also offers automated report generation and notification features, ensuring that critical insights are delivered promptly.

4- Unified Life-cycle Management:

- NetLume streamlines life-cycle management for all connected solutions, providing an automated and unified approach. This ensures that businesses can focus on strategic decisions rather than grappling with complex operational processes.

Conclusion:

In conclusion, the integration of IoT-based Remote Oil & Diesel Tank Monitoring Systems with NetLume’s advanced capabilities marks a significant leap forward in fuel management. The combined power of IoT’s real-time monitoring, predictive maintenance, and NetLume’s intuitive platform empowers businesses to achieve unparalleled efficiency, reduce costs, and pave the way for sustainable growth in the oil and gas sector. Embrace the future of industrial IoT with NetLume as your trusted partner in optimizing fuel management.