In the dynamic landscape of precision manufacturing, Computer Numerical Control (CNC) machines have emerged as the backbone of innovation, enabling the creation of intricate designs with unprecedented precision. As the industry continues to witness substantial growth, the integration of Industrial Internet of Things (IIoT) with CNC machinery has ushered in a new era of possibilities. In this article, we delve into the transformative role of IoT in CNC machine monitoring and explore how NetLume, a pioneering IoT solution provider, is redefining the manufacturing paradigm.

The Marriage of CNC and IIoT:

CNC machines, driven by computer programs, have elevated manufacturing capabilities to unparalleled levels. However, the synergy between CNC and IIoT takes this capability to new heights, introducing a realm of automation and real-time monitoring that goes beyond the conventional scope.

1) Proactive Maintenance Scheduling:

One of the key advantages of integrating IIoT with CNC machines is the ability to schedule maintenance proactively. Through NetLume’s innovative IoT solutions, operators gain remote access to real-time data, allowing them to monitor machine conditions from anywhere. This remote monitoring facilitates the scheduling of inspections or repairs, with automated alerts notifying operators of potential issues such as temperature fluctuations, vibrations, or tool damage.

2) Enhanced Machine Uptime Monitoring:

IoT-based CNC solutions, empowered by NetLume, extend beyond scheduled maintenance to optimize machine uptime. Real-time alerts from CNC machines enable factories to take proactive measures, mitigating the risk of sudden breakdowns. By leveraging NetLume’s expertise, industrial establishments can enhance machine-to-machine synchronization, achieving operational excellence and reducing downtime.

3) Elevating Worker Safety:

In the pursuit of Industry 4.0, IIoT contributes to improved worker safety by reducing manual efforts and minimizing the potential for injuries. Through seamless machine-to-machine synchronization, CNC machines can communicate and perform tasks automatically. NetLume’s IoT solutions support the development of smart robots that execute specialized and delicate work, reducing reliance on manual labor and enhancing overall workshop safety.

NetLume’s Distinctive Approach:

As a leading IoT solution provider, NetLume offers a comprehensive suite of tools and features tailored for seamless integration with CNC machines. What sets NetLume apart is its commitment to delivering end-to-end solutions with a unique blend of low-code to no-code interfaces.

1) Intuitive Design Capabilities:

NetLume’s platform empowers users to design their CNC machine domain models effortlessly through a user-friendly drag-and-drop interface. Whether configuring connectors for data ingestion or deploying analytics, the process is streamlined with a no-code approach, facilitating rapid prototyping of assets and systems.

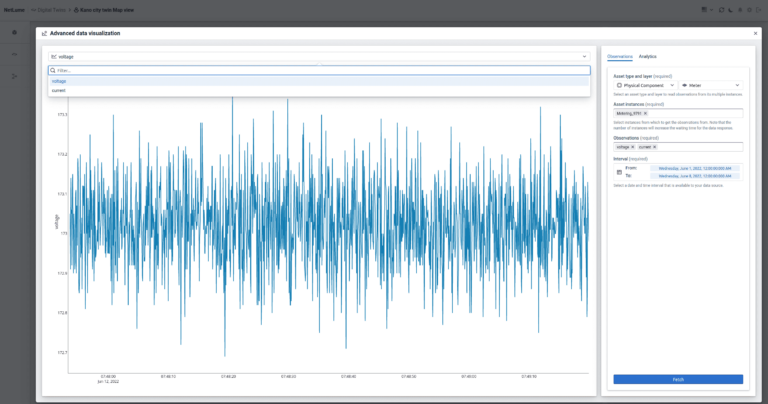

2) Real-Time Insights and Monitoring:

The platform’s highly customizable map visualization provides real-time insights into CNC machine networks. NetLume allows users to connect AI models seamlessly to the map, offering a holistic view of operations. Custom dashboards, automated report generation, and notifications further contribute to an enriched monitoring experience.

3) Unified Lifecycle Management:

NetLume simplifies the complexities of lifecycle management for connected solutions. Through automated and unified processes, the platform ensures a seamless experience from design to deployment, optimizing the efficiency of CNC machines.

Conclusion:

In the evolving landscape of precision manufacturing, the convergence of CNC machines and IIoT is reshaping industry norms. NetLume’s innovative IoT solutions play a pivotal role in maximizing the potential of CNC machinery, offering proactive maintenance, enhanced uptime, and elevated worker safety. As manufacturing embraces the era of interconnected machines, NetLume stands at the forefront, providing a transformative platform that propels CNC machine monitoring into the future. Connect with NetLume today to embark on a journey towards a smarter, more efficient manufacturing ecosystem.