In the fast-paced landscape of industrialization, ensuring safety within hazardous environments is a paramount concern for companies dealing with harmful gases or toxic substances. NetLume, a trailblazing All-In-One Data platform for AI applications and Industrial IoT, offers a cutting-edge solution to enhance industrial safety through its innovative IoT-powered Gas Monitoring System.

The Imperative for Smart Gas Monitoring

Industries such as tank farms, where large quantities of fuel are stored, face the constant risk of accidents due to gas leaks. The repercussions of even a minor leak can be catastrophic, resulting in significant losses. Recognizing the need for a highly advanced and technical solution to detect and prevent such mishaps, companies are turning to smart gas monitoring systems.

In the realm of IoT technology, the gas industry is witnessing a transformative wave, leveraging applications and solutions to bolster operational efficiency. The implementation of NetLume’s IoT-powered gas monitoring system emerges as a strategic move for industries seeking a comprehensive solution to detect various gases and enhance overall safety measures.

NetLume’s Distinctive Approach

What sets NetLume apart is its comprehensive All-In-One Data platform, allowing industries to model their domain effortlessly. With a user-friendly drag-and-drop interface, companies can design their domain model, define key components, and seamlessly connect them for a holistic representation of their industrial landscape. This no-code to low-code approach simplifies the process, enabling rapid prototyping of assets and systems.

Key Features of NetLume’s IoT-Powered Gas Monitoring System:

1-End-to-End Services: NetLume’s solution provides end-to-end services for better industrial growth, delivering data-driven insights to optimize and control plant operations.

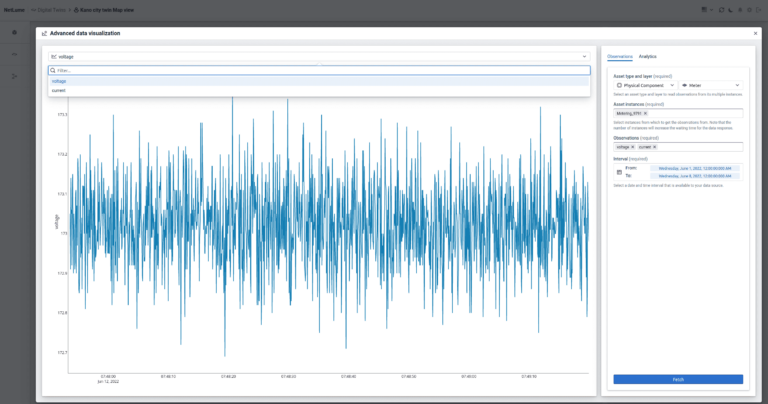

2-Real-Time Monitoring: Activated sensor devices continuously monitor the environment, promptly identifying any gas leakage and triggering real-time alerts through a user-friendly dashboard.

3-Custom Dashboard Design: Users can design custom dashboards with a rich library of visualizations, enhancing the analysis of gas monitoring data. Automated report generation and notifications further streamline decision-making processes.

4-Unified Life-Cycle Management: NetLume offers automated, unified, and simplified life-cycle management for all connected solutions, ensuring seamless integration and maintenance.

5-Low-Code to No-Code Interface: Designing AI models and data pipelines is made accessible through NetLume’s low-code to no-code interface, empowering users to deploy analytics with ease.

Applications Across Industries

NetLume’s IoT-powered gas monitoring system finds versatile applications across industries:

1-Flammable Gas Monitoring: Effectively detects flammable gases like hydrogen, acetylene, oxygen, and methane, ensuring worker safety and preventing fires. Early detection enhances asset performance.

2-Toxic Gas Monitoring: Identifies toxic gases such as sulfur dioxide, hydrogen sulfide, benzene, and inert gases, crucial for maintaining a safe working environment in industries like refineries and petrochemical plants.

Transforming Business with NetLume

For industrialists prioritizing safety and seeking to transform their business models, NetLume’s IoT-powered Gas Monitoring System proves to be a game-changer. By leveraging this solution, businesses can resolve issues related to gas leaks, empower themselves as industry leaders, and enhance overall productivity.

As an IoT leader, NetLume provides not just a solution but a holistic platform that revolutionizes the way industries approach safety. With its intuitive interface, real-time monitoring capabilities, and seamless integration of AI models, NetLume ensures that adopting IoT-powered gas monitoring is not just a measure for safety but a strategic move towards operational excellence.

In a world where safety is non-negotiable, NetLume stands as a beacon, guiding industries towards a safer, more efficient future.