In an era where passenger satisfaction hinges on the timely and efficient operation of rail networks, the traditional approaches to maintenance have proven inadequate. The prevalence of delays, often caused by asset failures, highlights a crucial need for a transformative solution. Enter the era of Predictive Maintenance (PdM) in railways, an innovative strategy empowered by the Internet of Things (IoT). In this article, we delve into the best practices of predictive maintenance in railways, exploring the potential of IoT technologies. Additionally, we’ll showcase how NetLume, a pioneering IoT leader, is at the forefront of this revolution, offering unique solutions that go beyond the ordinary.

The Landscape of Predictive Maintenance in Railways:

The imperative for Predictive Maintenance (PdM) varies across regions, depending on the traffic load of specific railway networks. In the UK, where passenger dissatisfaction with delays is notable, and in the US, where increased demand stresses infrastructure, the need for a reliable PdM system becomes evident. Traditional maintenance approaches fall short, emphasizing the urgency for a paradigm shift.

Applying Predictive Maintenance in Railways:

Predictive Maintenance is an approach that focuses on vulnerable components, allowing service activities to be carried out proactively before the probability of failure reaches critical levels. Leveraging real-time data from IoT sensors, this method calculates the Remaining Useful Life (RUL) of equipment, enabling scheduled maintenance based on actual conditions rather than statistical projections.

Key Components of Predictive Maintenance Solutions:

1-Sensor-based and External Data Collection:

- Equipping rail assets with IoT sensors enables continuous and remote monitoring.

- Integration of historical data, field inspections, engineering parameters, remote control systems data, asset management data, and external data enhances the accuracy of predictive models.

2-Data Transmission to the Cloud:

- Reliable connectivity is crucial for real-time or near real-time data transmission.

- Protocols such as MQTT, XMPP, AMQP, or WebSocket ensure effective Predictive Maintenance using machine learning.

3-AI-based Data Analysis:

- Relevant status indicators are analyzed to build robust predictive-analytical models.

- Cloud-based AI deployment processes real-time field data, providing accurate predictions on RUL and generating insightful reports.

Predictive Maintenance Use Cases in Railways:

1-Level Crossings:

- Hardware sensing gate opening angles enables tracking of deterioration over time.

- Automatic planning of maintenance activities based on predictive algorithms.

2-Bridges:

- IoT-based analytical tools predict failure by combining data on static and dynamic loads.

- Vibration diagnostics and continuous monitoring identify potential structural issues.

3-Tunnels:

- IoT sensors provide visual and sonic inspections to identify issues like seepage and corrosion.

- Complete data analysis optimizes maintenance strategies for long-term structural health.

4-Signalling Infrastructure:

- Condition-based maintenance is enhanced by real-time monitoring of track circuits, switches, and axle counters.

- IoT solutions with additional sensors ensure prompt data transmission, reducing incident-response time.

NetLume’s Unique Approach:

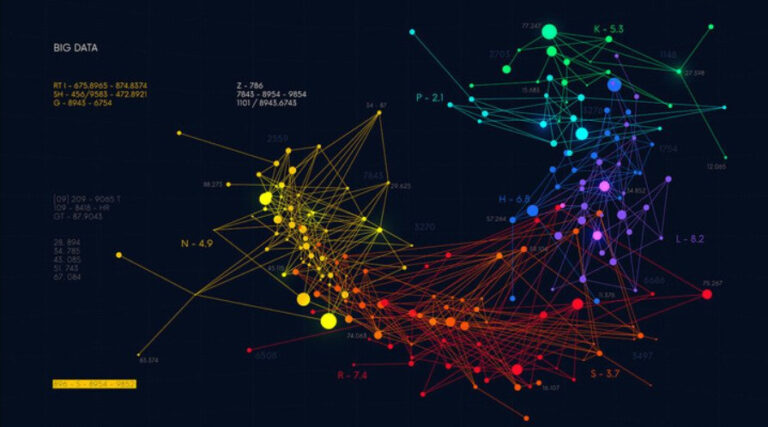

NetLume stands out in the IoT landscape with its All-In-One Data platform for AI applications and Industrial IoT. The platform’s low-code to no-code interface empowers users to design AI models and data pipelines effortlessly. With NetLume, railway operators can benefit from:

Rapid Prototyping:

- Intuitive drag-and-drop features for quick asset and system prototyping.

Real-time Monitoring:

- Highly customizable map visualizations with the ability to connect AI models for advanced insights.

Custom Dashboard Design:

- Rich library of visualizations, automated report generation, and notification features.

Unified Lifecycle Management:

- Streamlined management for all connected solutions, reducing complexity and enhancing efficiency.

Conclusion:

As predictive maintenance gains momentum in the railway industry, the synergy between IoT technologies and NetLume’s innovative solutions emerges as a game-changer. By embracing the power of real-time data, analytics, and proactive maintenance, NetLume is reshaping the future of railway operations. The era of delays and dissatisfaction is giving way to a new frontier of efficiency and passenger satisfaction, driven by the transformative capabilities of Predictive Maintenance and NetLume’s cutting-edge IoT platform.