In the ever-evolving landscape of industrial efficiency, the role of comprehensive IoT solutions has become more pivotal than ever. As industries strive to optimize their plant operations, the integration of cutting-edge technologies becomes a game-changer. NetLume, a leading IoT platform, stands out in this arena, providing a unique approach to boosting plant efficiency through its innovative solutions.

Unleashing the Power of IoT in the Energy Sector:

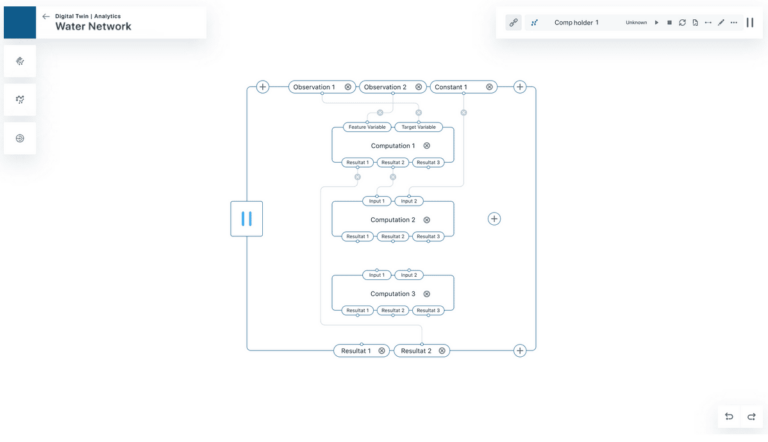

Plant efficiency serves as the lifeblood of industrial setups, influencing production rates and revenue gains. The Internet of Things (IoT) emerges as a transformative technology, enabling remote monitoring of plant performance. NetLume’s IoT solutions go beyond conventional approaches, offering comprehensive tools that redefine operational methodologies and highlight anomalies that could lead to unexpected plant shutdowns.

Preventing Downtime: A Crucial Challenge in Industrial Operations:

Pumps and compressors, fundamental to various industries, can become potential sources of industrial accidents if not properly maintained. NetLume IoT addresses this challenge head-on, providing real-time monitoring and advanced analytics capabilities. By focusing on a practical use case, let’s explore how NetLume IoT ensures operational excellence in a simple industrial setup.

NetLume IoT in Action: A Case Study in Plant Efficiency:

Imagine a scenario where a pump extracts water from a tank, serving as a coolant in a heat exchanger. NetLume IoT integrates seamlessly into this setup, employing sensors to monitor water levels, pressure, and temperature. The platform’s real-time alerts and analytics play a pivotal role in avoiding critical incidents such as pump bursts and low water pressure, ensuring uninterrupted plant operations.

A. Avoiding Pump Explosions:

NetLume IoT employs a level monitoring sensor and a pressure meter to detect irregularities in pump operation. If the water level remains unchanged during pump operation, authorities receive an alert, preventing potential explosions. The pressure meter further confirms the issue by showing zero readings, signaling a need for immediate attention.

B. Enhancing Heat Exchanger Efficiency:

Efficiency in the heat exchanger depends on water entering at high pressure. NetLume IoT’s temperature sensor at the heat exchanger’s exit identifies deviations from expected temperature ranges. This enables operators to quickly address issues related to low water pressure or malfunctioning pressure meters, minimizing downtime and optimizing overall efficiency.

NetLume IoT for Operational Excellence:

Beyond the specific use case, NetLume’s IoT solutions offer a versatile toolkit for companies seeking operational excellence. By continuously monitoring various variables and providing actionable insights, NetLume empowers companies to reduce unexpected breakdowns, streamline maintenance procedures, and enhance the overall efficiency of their plants.

Conclusion:

In the quest for unparalleled plant efficiency, NetLume emerges as a beacon of innovation in the realm of IoT solutions. By seamlessly integrating into industrial setups, the platform revolutionizes the way companies monitor and optimize their operations. As industries embrace the future of IoT, NetLume stands at the forefront, providing not just a platform but a comprehensive strategy for achieving operational excellence. Boost your plant’s efficiency with NetLume’s transformative IoT solutions, setting new standards in industrial performance.