In the dynamic landscape of tank manufacturing, the integration of IoT-based solutions has emerged as a game-changer, offering unprecedented efficiency and cost savings. As industries seek innovative ways to streamline operations and enhance productivity, NetLume, a pioneering All-In-One Data platform for AI applications and Industrial IoT, stands out as a leader in transforming the tank manufacturing sector.

The Evolution of Tank Manufacturing with IoT

Real-Time Insights for Informed Decision-Making:

NetLume’s IoT-based solutions empower tank manufacturers with real-time monitoring capabilities. Through cost-effective and ready-to-use deployments, these solutions leverage advanced algorithms to provide accurate data. This translates into on-the-spot decision-making, improved operational outcomes, and insightful data for sustainable business growth.

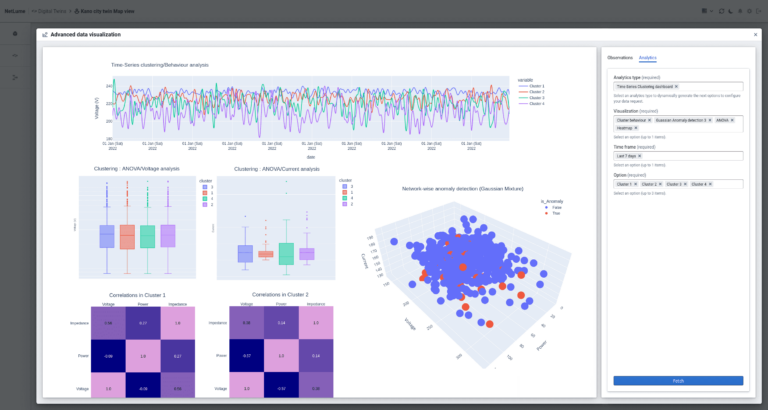

Strategic Advanced Analytics:

Embedded sensors on storage tanks gather relevant data transmitted through gateway connectivity, facilitating easy access. NetLume’s advanced analytics, driven by powerful algorithms, enable profound data analysis and result-oriented decision-making. This leads to increased productivity and informed choices, propelling businesses toward greater growth.

Automated Data Management for Seamless Operations:

The introduction of IoT in tank manufacturing brings automated data management to the forefront. NetLume’s platform ensures recorded checks on every activity within the factory equipment or tank storage capacities. This automated approach simplifies industrial tasks, allowing managers to focus on business growth, unburdened by traditional stock methods.

Asset Interconnectivity for Optimal Efficiency:

NetLume’s IoT solutions emphasize asset interconnectivity, creating smart systems capable of self-correction and predictive actions. Through continuous monitoring of assets—location, value, condition, and work status—NetLume enables optimized inventory and automated business processes. This not only accelerates operations but also leads to substantial cost savings.

Predictive Maintenance for Operational Excellence:

In the tank manufacturing sector, NetLume’s IoT technology enables predictive maintenance schedules by identifying potential asset flaws through sensor-based information. This proactive approach significantly decreases operational and maintenance expenses, contributing to overall profit growth and rapid progress in the industry.

Detailed Supervision for Informed Decision-Making:

NetLume’s IoT-based tank monitoring facilitates smart supervision through sensor devices and gateway connectivity. By tracing data from assets and storing it in a cloud platform, NetLume ensures detailed supervision without requiring excessive managerial effort. The user-friendly interface provides illustrative reports, offering deep insights into industrial activities and empowering managers to make informed decisions.

Edge Computing for Real-Time Insight:

In today’s digitally-driven manufacturing environment, manual processes are no longer sufficient. NetLume’s IoT solutions incorporate edge computing, providing manufacturers with real-time insight into operations. This includes monitoring and responding to systems on the factory floor, handling abnormal conditions, and ensuring continuous feedback through advanced analytics.

NetLume’s Unique Contribution

NetLume’s All-In-One Data platform brings a unique blend of Low-Code to No-Code interfaces, allowing tank manufacturers to design their AI models and data pipelines effortlessly. With rapid drag-and-drop prototyping, real-time network monitoring, and a customizable dashboard design, NetLume empowers manufacturers to optimize their operations seamlessly.

By integrating NetLume’s IoT solutions, tank manufacturers can:

- Achieve unparalleled operational efficiency

- Reduce downtime and maintenance costs

- Enhance overall productivity

- Ensure compliance with environmental regulations

- Gain a competitive edge in the market

In conclusion, NetLume’s innovative IoT-based solutions redefine the landscape of tank manufacturing, offering a comprehensive suite of features that not only reduce costs but also pave the way for sustainable growth. As industries continue to evolve, NetLume remains at the forefront, driving technological advancements and shaping the future of IoT in tank manufacturing.