In an era characterized by the relentless influx of data, the challenge isn’t just collecting information but putting it to good use. This is particularly evident in the realm of power plants, where the quest for efficiency and sustainability is ongoing. In this article, we delve into the world of IoT smart sensors and explore how they’re transforming power plants, with a special focus on NetLume’s pivotal role in this revolution.

The Data Deluge: A Modern Dilemma

Consider this: your brain processes the equivalent of 34 gigabytes of information every day, a volume that could overwhelm an average laptop in a mere week. Collecting this deluge of data is one thing; translating it into actionable insights is quite another. This is where IoT smart sensors come into play.

IoT Smart Sensors: The Backbone of Efficiency

IoT smart sensors, the bedrock of the Internet of Things (IoT), are becoming ubiquitous in our lives. They’re in our smartwatches, regulating temperatures and lighting in buildings, and increasingly, they’re optimizing industrial processes and energy infrastructure.

The global smart sensor market is projected to surge, expected to reach nearly $78 billion by 2028, more than doubling its 2021 value of almost $32 billion.

MHI’s TOMONI: Harnessing IoT Smart Sensors

Digital platforms such as Mitsubishi Heavy Industries (MHI) Group’s TOMONI suite of intelligent solutions harness IoT smart sensors to extract operational data from power plants. They process billions of data points in real-time, leading to enhanced operating efficiency, reduced costs, and minimized maintenance and downtime.

The Rise of ‘Soft Sensors’

While fully automated power plants might still be on the horizon, platforms like TOMONI are automating individual plant operations. Smart sensors gather on-site power plant data, which is then transmitted to the TOMONI cloud. Here, potent machine-learning algorithms analyze the data to optimize operating conditions and maintenance requirements at each power plant.

Moreover, ‘soft sensors’ are emerging. These sensors can predict the quality of fuels used at a power plant by monitoring parameters like temperature and pressure. This real-time data, combined with traditional sensor data, empowers machine-learning models to optimize fuel efficiency, resulting in less fuel consumption for more energy production.

Real-time Smart Maintenance

Smart sensor technology doesn’t stop at optimizing operations. It also enables TOMONI HUBs to identify potential problems before they occur, which translates into cost-effective and timely maintenance. This prolongs equipment lifespans and contributes to a reduction in both operational costs and downtime.

The Sensor-Driven Future

Sensors are here to stay in a world driven by data. AI-enabled solutions and automation are reshaping possibilities across various sectors. In logistics, sensors on shipping containers streamline global supply chains by tracking their location, sea conditions, and arrival times.

Tomorrow’s sensors could be powered by vibrations, heat, or light, stored in supercapacitors. They might even be fueled by human movement, revolutionizing health monitoring. The potential applications are boundless, from the human body to energy infrastructure.

NetLume’s Role in the Efficiency Revolution

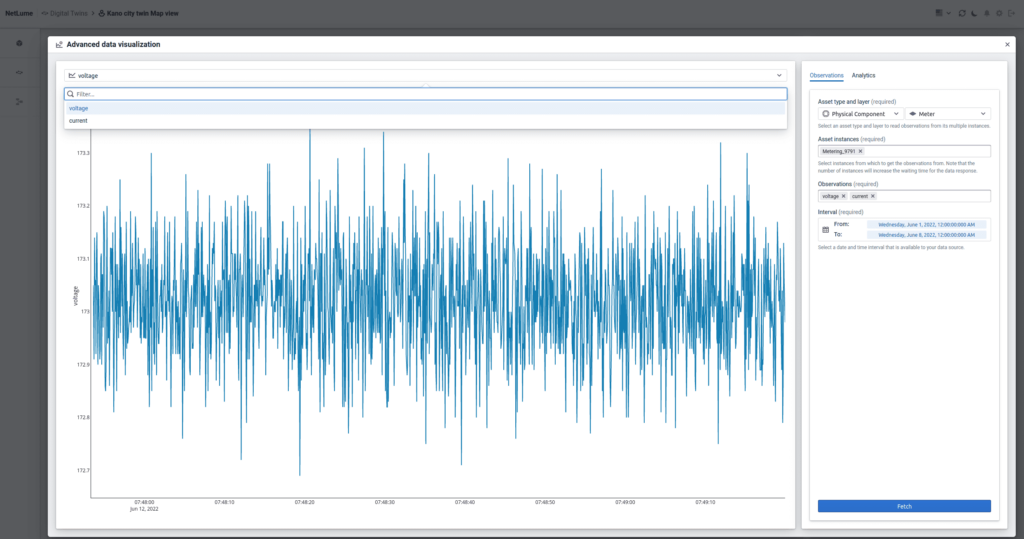

NetLume, an IoT leader, stands at the forefront of this efficiency revolution. Their all-in-one data platform empowers businesses to model and optimize their domains effortlessly. With a user-friendly, low-code to no-code interface, users can design and deploy AI models and data pipelines swiftly.

Some of the benefits of NetLume include:

- Rapid drag-and-drop prototyping.

- Real-time network monitoring with customizable map visualizations.

- Custom dashboard design with automated reporting.

- Unified and simplified lifecycle management for connected solutions.

NetLume enables businesses to leverage IoT smart sensors effectively, providing a seamless transition to an era of enhanced efficiency and sustainability in power generation.

In a world driven by data, the potential of IoT smart sensors in power plants is undeniable. The combined force of IoT technology and platforms like NetLume is propelling us towards more fuel-efficient, cost-effective, and sustainable power generation. By optimizing operations, predicting maintenance needs, and minimizing downtime, power plants are on the cusp of a transformation that benefits both the industry and the planet.